このプロジェクトで何千ドルも節約できました!! 原木から階段の踏み板を作る #木工 #DIY

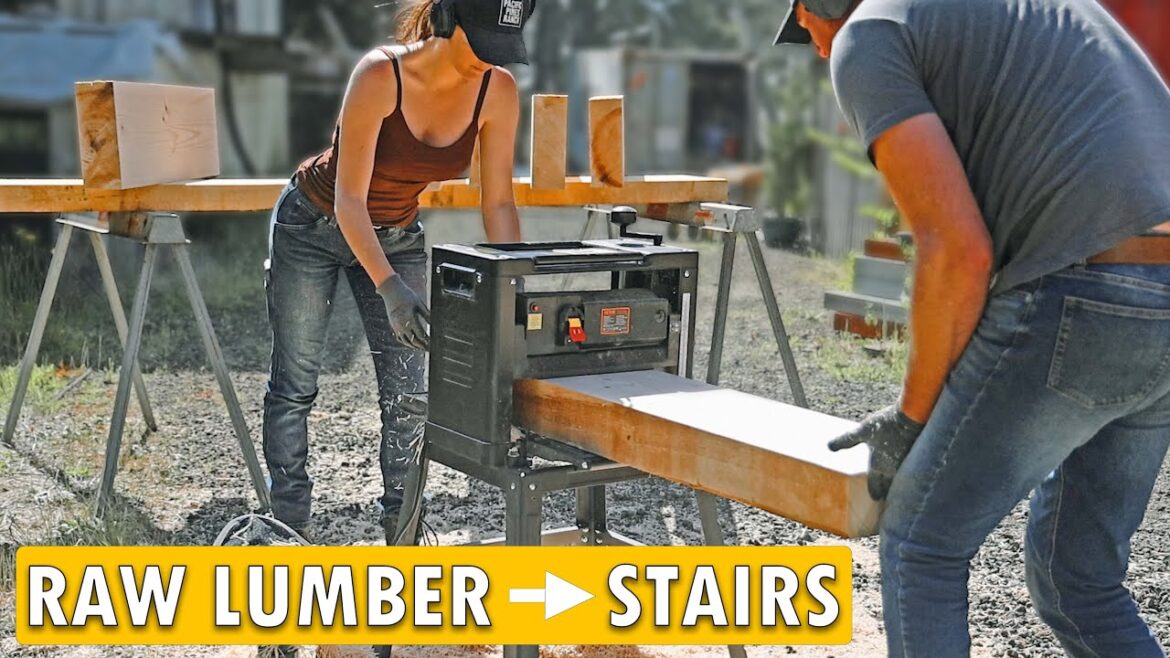

[Music] today we are back at it working on the stair treads for our floating staircase so we tipped down a tree on our property and milled all of these stair treads with the help of Tony if you missed those last two videos be sure to check them out they’re definitely entertaining it’s been a crazy journey to get here but anyways they’ve been drying for a little while and now we are going to work on the next steps with prepping them so we can get them installed and all set up so let’s get rolling first thing we had to do was try to find some wood stains which turned out to be harder than we thought we ended up buying several different color variations that we test out later in the video so stay tuned to see the results beautiful [Music] [Applause] day today out on the ranch and how are we going to spend this beautiful day by building our new wood planer the Beaver Thick Nesser all right let’s set this up [Music] all right so we just finished setting this up that kind of took a little bit of time it was not so easy to follow the directions they were very vague but we did it so now what we’re going to do is grab some of the extra pieces of wood that we mil so it’s the same wood and play around with them figure out how the machine works and hopefully get around to testing out some of the stains but we’ll see so this is a chunk of wood off one of the end of the stair treads so I think we’re going to try to kind of figure out how everything works with some scrap pieces first get an idea of how to run the machine and then continue on [Music] so one thing that’s really annoying is all of the measurements on this planer are in metric so it’s all millimeters so we’re going to have to do a little bit of converting to make it work for what we want to do but thank God I have this little measuring tape that does both oh yeah nice uh metric and imperial ikea to the rescue [Music] how much did it remove 116 only good oh man do you want to do the stairs a little bit all right let’s see if we can make it take off a bit more i don’t know to walk but let’s see [Music] okay so I think we got a handle on how the planer is working now what we’re going to do is grab one of the stair treads and run it through the planer a few times and see how that turns out so let’s grab a tread [Music] [Music] little bit above okay can you see on the camera yeah like this side is a little bit more thick than this one okay let’s see the other side i guess we got to less pass mhm okay so this one less so 4 in and a quarter oh and here it’s a little bit more yeah 4 in and quarter too okay so it’s a little bit bumpy over there but not by much all right we said was a square one honestly we kind of struggled a little bit learning how to use the planer eventually we figured out that we had to remove the dust collector with the vacuum outlet and replace it with the regular dust hood because it was getting clogged up while running after that and finding the good depth settings we were ready to roll okay so I think we got an idea of how this works and we can move along with planing the first tread to kind of get somewhere set up a protocol and uh move on from there after that we are going to run one of the scrap pieces through the planer so that we can test the stains that we have to see what they look like so stay tuned for that going out [Applause] [Music] [Applause] guys [Music] [Music] so that went pretty well pretty happy with how they’re turning out now we’re going to grab a piece of scrap and run it through the planer a few times to make sure that it’s flat and then stain it and try to figure out what stain we want to go with there’s crazy birds flying everywhere it’s wild anyways let’s roll okay so let’s measure measure this side [Music] okay pretty good almost 4 in we have to send it a little bit and yeah and the other side oh pretty much good to go so nice clearly we still need to clean up the the vertical sides but the planer can’t fit the treads vertically so we are going to have to do something else for those sides but this is looking really great really happy with how it’s turning out yeah like send a little bit here and here yeah i’m in Berlin amazing like very fast singing oh my god [Music] all right like a bunch but that would be a good uh good test for the do even less we go up a little bit so we do one like that let me see uh okay one down okay uh maybe one down a little up down i like that next try like that [Music] okay so we got this piece pretty as good as we want it so we’re just going to cut it like somewhere about here and then bring it over here on the saw horses sand it a little bit and then stain a few parts to see what they look like so let’s see how it goes [Music] [Applause] [Music] we wanted to test out a wide range of colors because we’re not sure which ones we like yet this is an idea of the overall vibe that we’re going for so we wanted to test both light and dark colors to see how they look we hope we can find a cool toned color that will work well with the aesthetic we want to create so we got all of our stains here and we’re just going to go one by one and test them along this board let us know in the comments which one you guys prefer i’m going to write the name of each stain above where we stain it [Music] all right you guys here are our results so far we’re not like super crazy about any of them in particular these I just did kind of like a diluted paint just to see kind and actually this one is really not that bad but I don’t know so this one is sunbleleached this one is classic gray this one is western oak this one is driftwood this one is dark walnut and this one is kona so drop a comment below let us know which one do you guys prefer we still don’t know which one we prefer we’re trying to figure it out my favorite is a western oak but I’m not like totally in love with it but it’s my favorite between all of them yeah so let’s see how it evolves here’s how they look against the staircase which will be black [Music] as you guys know we try new things all the time on the ranch but it’s often hard to find resources to guide us we are passionately curious people what if you could turn your curiosity into man these are heavy [Music] it was a little bit time consuming and challenging to figure out how to use a new tool and to set up a good workflow we struggled a little bit with figuring out a good way to organize and process the stair treads especially because they are really heavy but eventually we figured out a good way to go about it and got started [Music] all right so we got all of the treads down to 4 and 1/4 in we need them to be 4 in so now at least they’re all the same size and we can run them through the planer until they’re 4 in so so far everything’s going well it’s just it sometimes it just takes time to kind of figure out a good way to go about doing stuff so took us a minute to get set up but now we’re rolling let’s see if uh [Music] [Music] [Applause] [Music] [Music] [Music] Heat heat [Music] [Applause] heat heat [Applause] [Music] [Applause] [Applause] [Music] [Music] heat hey Heat [Applause] [Music] [Applause] [Applause] [Music] [Applause] [Music] [Music] heat heat [Music] ah [Music] all right we’re getting close one pass and we good I think so let’s let’s check the measurements okay oh yeah yeah one pass because after we have the sanding and Yep yep and maybe they will shrink a little bit more so nice we still have to do the sides and kind of sand the ends but at least we got the uh horizontal parts planed [Music] last tread for the day [Music] [Music] yay we finished woohoo i mean we finished we did that we did that so we got these ones all finished we still have let’s see how many do we have six right here right one two three four one that we did yesterday to test so seven and we have 13 treads yeah so six more tomorrow okay good start good job now we’re basically just going to um cover everything for the night and uh what is happening and call it a day and get back at it tomorrow [Music] [Music] so now we’re going to try to organize them by size because some are a little bigger and some are a little smaller eventually we will even that out with the planer but maybe it will help us save time uh passing a board through kind of for no reason if it’s like way smaller so we can get the bigger ones close enough to the smaller ones and then do all them [Music] [Music] heat heat [Music] oh [Music] hey [Music] ooh ooh ooh [Music] yeah yeah yeah [Music] once we finished planing all the stair treads we grabbed the leftover slab we tested the stains on and ran it through the planer a few times since we’re not really set on any particular wood stain we’re going to test a few others and see if anything really catches our eye [Applause] [Music] [Music] okay we went to go get the table saw to work today and a hummingbird went in the house and wouldn’t get out so look at this there’s a little hummingbird in there i think he’s very tired though hi buddy i hope he’s not dead dang did he kill himself it was so fast this is crazy this is insane that was wild yeah wow so today we are going to be working on the vertical part of the stair treads making them square and planing them etc etc us we have our table saw that we’re going to be working with and uh a joiner I think it’s called um to kind of like plain the sides cuz they’re too thick to fit in our wood planer but we did a few more patch tests for the color so let’s check it out so the So the back side of this we didn’t like any of them on the other can you show the other side yeah we just I don’t know we didn’t really like any of those so we said no to all of those then we tried um these three this is just clear coat uh and two other colors and now we just tried these ones and I think we might have a winner i just put clear coat on the top of these to see what it looks like so we’re going to have to wait for that to dry a little bit but I think in between this one which is called Discovery and this one which is called Monteray but I don’t know this one’s a bit light we really like this one so we’ll have to see this one’s too green you think this one is too dark cuz at the end of the day it’s not too bad either huh yeah so we’ll see too much choice kill the choice all right you guys we are pretty much ready to start using combination of the table saw and the joint jointer I think it’s called uh let’s give you a rundown on what we’re going to be doing so first we’re going to run the stair treads through the this is a jointer right yeah jointer joiner okay uh shave off the bottom so we get one flat edge then because these are all a little bit bigger than we need then we’re gonna come over here to the table saw put the flat edge against here and cut the width that we need bring it back over here run it through one more time just to smooth out the edges and that’ll be that next one one after the other yeah so let’s get started hopefully that won’t be too hard and it won’t take too long but like I say so many times I don’t want to jinx it [Music] [Music] [Applause] [Music] [Music] all right let’s check beautiful and square look at this really nice perfect really nice that’s great should we Should we measure it now oh maybe we have to do another pass you want to do another pass or maybe that will shrink uh I think we shouldn’t i think we should leave it cuz you’re less than an eighth and I still need to sand it so I think we’re good [Music] hey hey hey [Music] [Music] [Music] hey [Music] hey hey heat up here [Applause] [Music] [Music] [Music] these ones we have some work yeah this side is not too too bad so we plan this side first and cut the Yeah and those one they look pretty good actually not too far off yeah there’s only there’s only three I think that are pretty intense this one is bad this one and that one over there if not all the other ones are all right let’s see yeah okay now we’re going to do these ones these are the last ones and then we’ll work on the uh the ends [Music] [Music] h check this out nice this one nice one micron you can see the light oh oh yeah this one is not perfect almost perfect yeah but close you can fit the air on this side and it’s perfect cool very nice looking good [Music] [Music] hey hey hey [Music] [Music] yeah yeah [Music] [Applause] [Music] hey hey hey [Music] all right we just finished for the day got everything accomplished that we wanted to now all the stair treads are square and planed and all set up and ready in the good length yeah in the good length and all set up and ready to be finished so next up we’re going to be choosing which stain we like the best and uh yeah sanding them and finishing them so one step further let’s check out what we did so here are our beautiful treads they look amazing super happy with how they are turning out they are just so beautiful and special considering it’s a tree from our land so be sure to subscribe if you haven’t already subscribed to see how they turn out thank you guys so much for watching another video on Pacific Pines Ranch and we’ll see you guys in the next video another day of learning new skills and learning how to use new tools the stair treads are turning out amazing it was quite a bit of work to get to this point but overall it was worth it the stair treads are not only super beautiful they come with a story and have meaning i can’t wait to stain them and install them to see how everything will look once it’s put together stay tuned help support our channel by leaving a comment liking and sharing this video as always you guys thank you so much for watching don’t forget to subscribe to keep up with our projects and adventures on Pacific Pines Ranch we put out new videos every Saturday and sometimes even during the week so be sure to subscribe and hit the notification button so you don’t miss any okay bye [Music]

*SKILLSHARE*

Get started here: https://skl.sh/pacificpinesranch06251

The *FIRST 500 PEOPLE TO CLICK MY LINK* will receive *20% OFF* their first year of Skillshare!

Don’t miss out on this incredible deal and start creating today

In previous videos, we cut down a tree and milled it into thick wooden slabs/treads. Now, we’re taking the next step—processing those treads with tools we’ve never used before! Follow along as we shape, sand, and prepare our custom stair treads for installation.

🔨 *What’s in This Video:*

-Processing rough-sawn lumber into finished stair treads

-Trying out new tools for precision shaping

-Progress on our DIY stair build from tree to installation

🌲 *Watch the Series:*

Part 1: Felling the Tree [https://youtu.be/ReJN7bLRlSw?si=dEB4MEf366lsoIFW]

Part 2: Milling the Lumber [https://youtu.be/Hx2mQq18DVE?si=UiksgWLmagS6VBzV]

Part 3: Shaping the Treads (You’re Here!)

💬 Let us know in the comments: Have you ever built stairs from scratch? What tools do you recommend for working with raw lumber?

👍 Enjoy the video? Don’t forget to *Like, Subscribe, and hit the Bell* to stay updated on our projects and adventures on Pacific Pines Ranch!

*TO SEE MORE OF OUR CONTAINER HOUSE BUILD, CHECK OUT THIS PLAYLIST:*

This playlist starts from the very beginning of our project!

*Don’t forget to check out our website and store:*

https://www.pacificpinesranch.com/

We have PDF plans of our container house and all proceeds help support the channel!

*SOCIAL MEDIA PAGES:*

Instagram – https://tinyurl.com/hkfvf7vs

Facebook – https://tinyurl.com/44h7546v

TikTok – https://tinyurl.com/nd86s2nc

YouTube – https://tinyurl.com/yc4h3c53

*ABOUT US – PACIFIC PINES RANCH*

After spending several years living the “city life”, we decided we wanted a change. We sold almost all of our possessions, renovated a camper van, and toured the US looking for a piece of land to start our journey. After almost 2 years, we found our piece of paradise in the Pacific Northwest, and Pacific Pines Ranch was born. It’s our goal to be as self sufficient as possible and learn as many new skills along the way as we can. Pacific Pines Ranch was built on the principles of repurpose, repair, and reuse, and that can be seen throughout the property and the container build. Our three story shipping container house consists of 7 containers, and we plan on learning the skills and trades to do almost all of the work ourselves. PRETTY AMBITIOUS, I KNOW. Our projects on the ranch range from home DIY projects, mechanic work, welding, woodworking, property development, foraging, fishing, adventures and anything revolving around building and tools. Follow along on our social media channels and *SUBSCRIBE* to join us on our projects and adventures on the ranch!

#containerhouse #containerhome #pacificpinesranch #construction #building #build #buildingconstruction #shippingcontainer #shippingcontainerhouse #shippingcontainerhome #tools #toolsofthetrade #welding #weld #fabrication #welder #woodworking #woodwork #diy #diyhome #diybuild #homeconstruction #homedesign #moderndesign #diyproject #diyprojects #renovation #upcycle #recycle #renovate #architecture #architect #modernhome #modernhouse #toolsofthetrade #wood #lumber #woodworking #woodworker #stairs #staircase #milling #tablesaw #tools #finishing #woodwork #woodworkingtools #planing #moderndesign #interiordesign #jointer #custombuild #custommade #stairdesign #house #home #housedesign #homedesign

45 Comments

The first 500 people to click my link will receive 20% off their first year of Skillshare! Get started today! https://skl.sh/pacificpinesranch06251

Dark Walnut

Maybe try a pre-stain and then check the different stains. It will a big difference in how the stains look.

✌️❤️❤️💪

Western oak!!

To find what stain you really like, you’ll want to play around with mixing stains together. Even using “White-Wash” over the darker stains like Kona or Dark Walnut mutes or gives the look of aged or patina wood. Just suggestions.

Western oak

How about beveling the front edge.

Dark Walnut & Kona. The colors may change after you put a finish on it, like varnish over the stain.

As other have suggested, round over the front edge…a trip on the stairs could be quite painfull!

Cona or dark oak i like because it highlights the grain

I think the western oak will work best with the black. You might try to darken it a bit more. I have a bunch of colors and often times I mix things up. The reds and yellows might clash. Tom Johnson is an expert at making his own stains to match the antiques he repairs.

VALE, VALE, VALE, VALE, VALE, VALE, VALE IA Are in dippers, wemall people from latinoamerica hate how people fron spain talk.

The European name for a finish carpenter is joiner. It is literal, one who joins wood together. If you are looking at hand planes, one is called a joiner plane, they are generally very long, 16 to 24 inches. I expect your friend has many of them also. I have 2 joiner planes, one is steel, and the other is wood (and a bunch more). If you ever watch Stumpy Nubs channel, he has well over 100 wooden planes and he knows how to use them. There is this satisfaction you get from using hand planes, it is addictive.

Driftwood looks best

I would recommend either a small round over on all the edges or a small chamfer to prevent chips and breaking

Dark Walnut

Driftwood and oak

Were you going to round over the top front of the treads? The crisp edge can be a bit hard on your feet.

I think the first step is to level one side first before plaining is what i seen them do on youtube

Dark walnut or Kona will bring some warmth into the space colour wise. Definitely hit the front edge with a round-over router bit; your feet will thank me later lol. Looking great guys, keep up the good work!

It’s too late now but, imo, you would have done better to thickness the boards before cutting to length. On a thicknesses that size it’s very hard to eliminate snipe where the planing begins and ends.

ME PERSONALLY i PREFER DARK WALNUT

Western Oak fits perfectly! The lighter colors are going to show dirt almost immediately!

Early American

I prefer the Western Oak and the Dark Walnut, but both of them seem to be a bit washed out. I think you need a more intense shade of them… Maybe double staining them might work?? I dunno. 🤷

Use Prestain/wood conditioner for pine for a richer less blotchy colored stain. You will be glad you did.

Love it so much keep it up as always 💘❤️❤️❤️❤️❤️❤️❤️❤️❤️😘💕💖💝😁😍

I vote for Western oak color. It looks great!

I didn't like number 4 but when paired with the Black it does look good. I would choose number 2 or 4 myself. 👍

I would like this question answered if someone know the answer…..I never used a Wood Planer myself….but lets you say you need a 1/2 inch off why can't you set it for that and do it in one pass?….Why does it take so many passes to get the Wood were you want it?.

Hey, when you do install them. Make sure the grain on the ends are frowned down. Because later when they cup the cup will be pressed against the metal will keep them flat. Raw wood moves. Humidity and temperature will expand and contract.

Well, you changed the stain options but I personally don't like the new choses but it's your Stairs. I would pick number 4 or 2 on the original Wood Stains myself.

Hi from Australia. Sending love from Australia.. I always enjoy your video,s.. Thank you for sharing your work.. GR8. Xx ❤..

All of those stains are horrible. Just let the timber speak for itself. A clear penetrating oil is your friend here. Danish oil, Osmo, something like that. You need super hard wearing finishes for stairs. They're a heavy traffic area.

Western Oak.

dark walnut

I’m just amazed at y’all’s ability to make everything look several levels above outstanding!

Stair treads are looking good! I'm a bit concerned about the wood as it dries since I believe the tree has only been down a short time and it hasn't been air or kiln dried from what I have observed on your videos. It generally takes about a year per inch of wood thickness to air dry. I recommend getting a moister meter and monitor the treads. Wood is considered to be dry when it is 12% or below. There might be future issues with cupping, twisting and end grain splitting. For best results place the cup side down when installing. I would definitely ease the top front of the tread to help from splintering from foot traffic. I would use a darker stain if they were mine. 🙂 Thanks for sharing. I enjoy your channel!

Clear polyurethane, oil based to give it a deeper “color”.

remember its foot traffic which means dirt , so i would select the middle

I like my Vevor trailer I pull behind my ebike but I think I will stick with my Dewalt thickness planner.

Dark walnut

🙏👌💐💐💐💐🥰🥰🥰❤️❤️❤️♥️❤️🎉🎉🎉🎉😢😢🥰🥰💐💐♥️♥️♥️

Dark wallnut